Our Services

OUR SERVICES

Doherty Steel offers a wide variety of steel finishing, fabrication and erection services. We also erect precast concrete and install handrail systems.

Services

Detailing

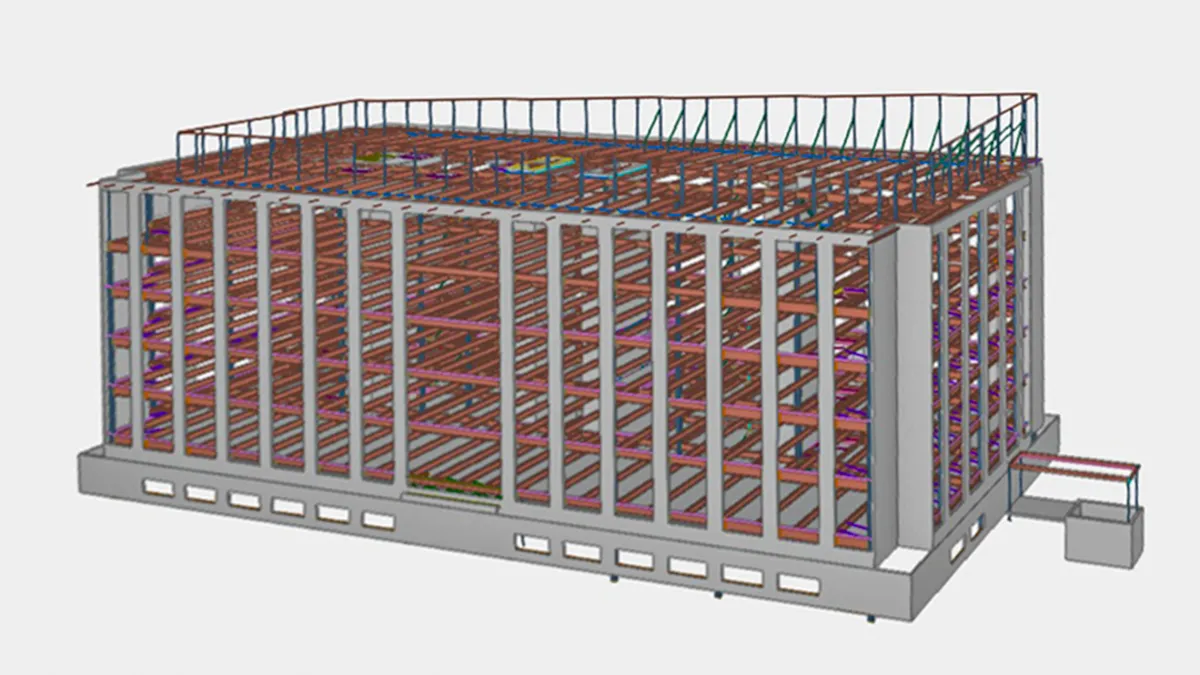

Steel detailing is the first step of many when getting ready to construct your building. Doherty Steel’s detailing department uses SDS2 to design connections and create 3D models. With automated design features that account for not only structural integrity and constructibility, but also erectability, SDS2 helps Doherty Steel to provide efficient, accurate, and cost-effective detailing services.

Dedicated to designing every detail, our steel detailers will ensure your structure will be supported and contains all the necessary pieces to get your project accomplished.

Our detail services include:

- Framing Plans

- Structural Steel Design

- Structural Dimensions

- Fabrication Shop Drawings

- Steel Connection Detailing

- Handrail, Beam, Deck, Joist & Stair Detailing

- Anchor Bolt Settings

- 3D Models